Manufacturers today are under immense pressure to extract maximum value from their supply chains while differentiating their products and services. Many are turning to digitization to innovate faster and discover new ways to deliver their offerings. Companies are accelerating adoption of digital technologies such as cloud computing, artificial intelligence, and machine learning for transforming their business operations from sourcing to customer management.

The Sourcing and Procurement function plays a major role in discrete manufacturing companies, which typically incur about 60% to 70% of their total spend on the procurement of materials and services. Intense competition results in a price war between the companies making adoption of cost-efficient strategies imperative. Procurement software for discrete manufacturers can enhance predictability in their supply chain by minimizing the risks and help in controlling spend more efficiently.

Table of Contents

ToggleProductivity Paradox in the Post COVID Era

Today, the world is in round two of the Solow Paradox. Earlier, in 1990s technological innovation brought a significant increase in productivity. After the Great Recession, there has been a significant drop in productivity growth due to shortages created by volatile demand and investment opportunities. However, following the Great Recession in 2007, productivity growth has stagnated.

Initially, during the ICT (Information, Communication and Technology) revolution, there was a huge decline in productivity growth. It was not because the technology wasn’t as transformational as previous other technologies that caused a boost in productivity growth. This decline can be attributed to companies’ failure to fully leverage new technologies. Currently, several companies are in the same stage. The pandemic has thrown light upon this disparity of productivity growth between the companies that are technologically equipped and the ones that are not.

Now more than ever, COVID had shown the importance of procurement in every manufacturing company that took a huge hit in their entire supply chain. The rapid variation in demand, the halt of the supply, and a tectonic shift of the market space had brought many companies to their knees. Companies that were technologically equipped had not only stayed ahead in the race but also saw an increase in productivity growth. COVID had forced businesses to use technology to its fullest and extract the maximum benefits. Numerous manufacturing companies have also revamped their procurement process and sourcing strategy that has transformed their supply chain significantly.

Procurement Trends for Discrete Manufacturers

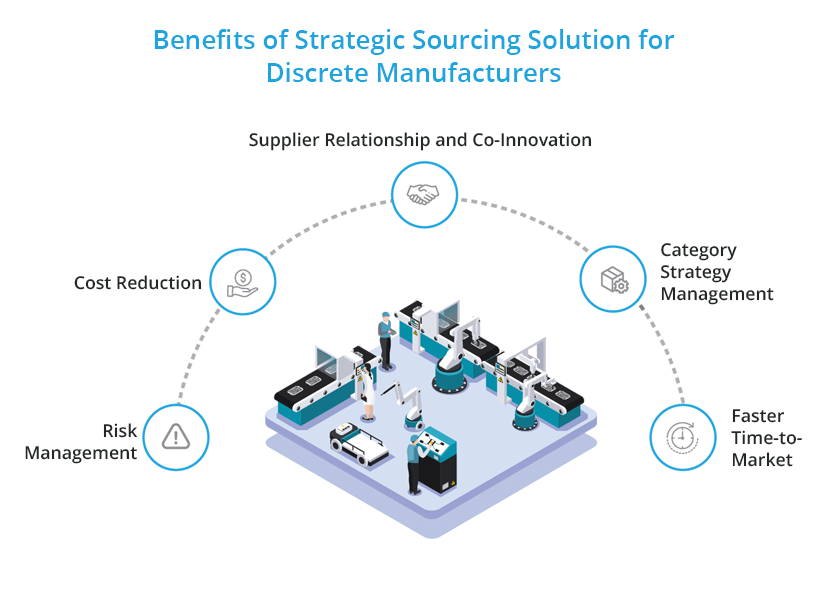

Companies must find innovative ways to improve themselves regularly. Procurement offers discrete manufacturers a variety of ways to improve their business processes and possess a competitive edge in the market.

- Risk Management: The time has come for companies to do a thorough assessment of supply chain risks and manage them proactively. Instability in the supply chain can cripple the company’s growth and as we have seen during the pandemic, it can even impact survival. Mitigating risks from sourcing would eliminate any ripple effects in the supply chain. Supplier Risk Management ensures stability of supply for the company. Sourcing software allows manufacturers to manage their supplier data, the core of every procurement activity, more efficiently. Having access to accurate supplier information is more critical when dealing with direct materials. Procurement software increases transparency throughout the supplier management process allowing companies to mitigate supply risks and ambiguities. It enables a definitive risk management strategy to companies to tackle any disruptive events.

- Cost Reduction: Strong Analytics feature in Procurement software helps companies to identify their non-value-added suppliers and eliminate them. Manufacturing companies have contracts with their suppliers and monitoring contracts is a tedious manual process. They are exposed to Maverick Spend more than any industry. Contract management and spend analytics allow companies to reduce their maverick spend. Spend Analytics would also help in recognizing the potential areas of direct spend to optimise and create new forms of competitive advantage. Automation of payments, receiving and invoicing also enables these processes to run smoothly and reduce operational errors and thus all related costs.

- Supplier Relationship and Co-Innovation: Supplier relationship is vital for a manufacturing company. With the fast-changing market, manufacturers must find innovative ways to ensure faster production and a reliable supplier base. Supplier partnerships can result in collaborative or joint innovation. A good sourcing platform would allow companies to pick the most suitable supplier who has an existing infrastructure or any complementary service and make it easier to establish partnerships and joint innovation with them to stay ahead of this evolving market.

- Category Strategies: Category Managers have an essential role in the sourcing of Manufacturing companies. A good category strategy is based on deeper insights on the current cost and spend patterns as well the future product roadmap of the company. For example, if customers are shifting to Electric Cars; Auto companies need to invest more in developing a supplier base in electrical and electronic categories. Consumer demands are constantly evolving, and companies must be at par with them. They would have to analyze the market dynamics regularly and formulate new category strategies that would help companies to capture or regain value through sourcing. Category Management is a module that can significantly increase the value in the procurement process.

- Faster Time-to-Market: Companies must reduce their NPI (New Product Introduction) time, to meet the fast-evolving customer needs. Engineering and R&D collaboration with Sourcing as well as Suppliers using technology makes this process efficient and scalable across product lifecycles. Real-time monitoring of the data would support the companies to adopt the NPI best practices. The ability to track changes in Engineering Bill of Material and analyse the benefits can speed up the NPI cycle over a period. It is a very critical feature for companies that have complex product designs to manufacture. The visibility of the supplier information to the engineering and sourcing teams can be utilized in strategic sourcing and operational planning, resulting in fewer delays and a more collaborative relationship.

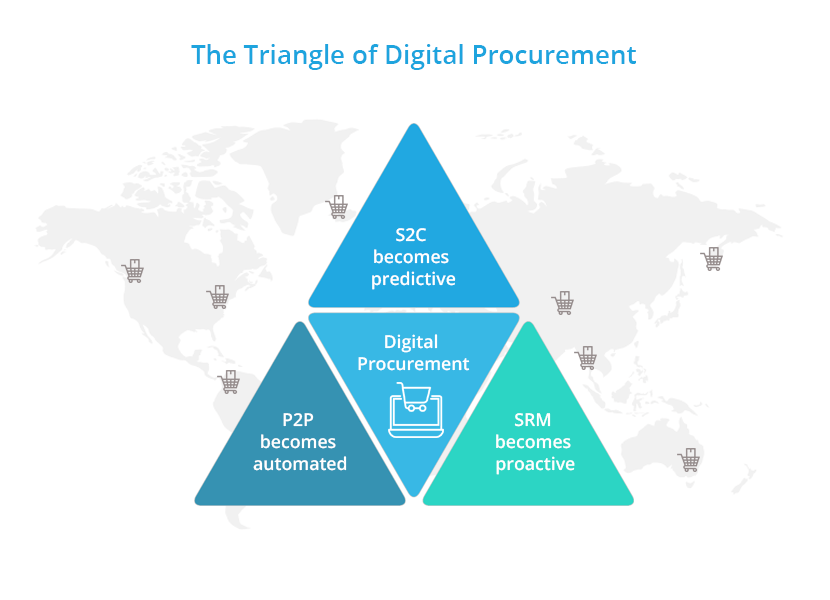

The Triangle of Digital Procurement

Digital procurement is increasingly becoming a cornerstone of competitive strategy in discrete manufacturing. Modern procurement solutions are categorized into three main areas:

S2C (Source to Contract): Categorizing and managing spend in real-time, predicting demand more accurately, recognizing future sources of supply and acting promptly on timely alerts from all the negotiated contracts defines the new S2C solutions. S2C enables data-driven decision making in the company with supply base, spend and costs visible to the procurement team in real-time. It allows them to attain optimal agreements with high-value suppliers.

P2P (Procure to Pay): This business process focuses in transactional aspects of procurement. It can automatically send requisition replenishment requests to the supplier by sensing the material demands of the organization. By leveraging RPA, this can streamline and automate the repetitive, voluminous, error-prone payment processes. It speeds up processing of purchase orders, requisitioning goods and paying invoices, and makes the entire P2P process more efficient and less prone to errors.

SRM (Supplier Relationship Management): It allows the organization to become more proactive in sourcing and helps in adopting strategic sourcing effectively. SRM also helps in mitigating supplier risks in real-time and allows supplier co-innovation to capture value in the procurement process. It enables companies to focus on continuously optimizing procurement operations and pre-emptively equip themselves with risk management strategies.

Procurement software offers discrete manufacturers a powerful toolset to improve efficiency, reduce costs, and stay competitive in an increasingly digital market. MeRLIN is a Strategic Sourcing software that has robust features suitable for Discrete Manufacturing companies. The Source to Contract solution has category management, supplier relationship management and spend analytics features that would help in implementing the best procurement practices for discrete manufacturers. It drives efficiency in the procurement processes to innovate and be more strategic. It helps to improve margins, mitigate risks, improve performance, and ensures a faster time-to-market.