W.Edwards Deming , an eminent author once said-“You must have a supplier relationship of constant improvement.” Managing supplier relationships continuously is key to achieving successful outcomes and long-term value for both the supply chain and your organization. But how can you build effective supplier relationships? This blog discusses the importance of supplier relationship management (SRM) and practical steps to develop reliable and lasting supplier partnerships.

Inhaltsverzeichnis

ToggleWhat is Supplier Relationship Management?

Supplier Relationship Management (SRM) is a structured process for evaluating and managing the vendors that supply goods, services, or materials to a business. SRM helps organizations identify which suppliers have the greatest impact on performance, cost, quality, and long-term growth. It also brings visibility into suppliers who may be underperforming or presenting risks.

Typically led by supply chain and procurement professionals, SRM links closely with operations, sourcing, and project management. A strong SRM framework relies heavily on an efficient supply chain management system because disruptions, delays, and visibility gaps can quickly weaken supplier relations.

The COVID-19 pandemic highlighted the need for stronger supplier risk management, better collaboration, and end-to-end visibility. Procurement teams are increasingly adopting SRM software and supply chain risk tools to monitor suppliers, track performance, and reduce vulnerabilities.

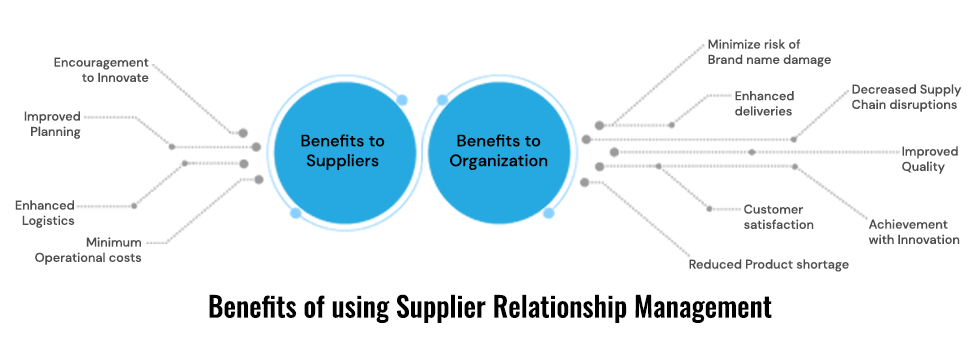

What are the benefits of SRM?

When executed well, SRM creates long-term strategic value and enhances supply chain stability. Key benefits include:

- Greater Efficiency

SRM streamlines communication between buyers and suppliers, eliminates redundancies, and ensures that business goals and expectations are clearly understood.

- Improved Revenue and Cost Savings

Strong supplier relationships open doors to cost efficiencies, better pricing, and new market opportunities. Both parties gain improved visibility into risks and growth areas.

- Continuous Improvement

SRM fosters a long-term improvement cycle where suppliers consistently meet performance expectations and align with the buyer’s quality, service, and innovation goals.

Embracing strategic supplier management techniques

Supplier management is not only about tracking suppliers or inventory. It requires structured, strategic collaboration.

Strategic SRM focuses on nurturing long-term partnerships, especially with suppliers critical to business continuity. The approach is built on:

- Mutual benefit for both buyer and supplier

- A well-defined, structured governance model

- Trust, accountability, and transparency

- Alignment across design, delivery, processes, and tools

Organizations increasingly rely on SRM technology to support these strategic frameworks and maintain consistency in supplier engagement.

How to develop effective and reliable supplier relationships?

To build strong, scalable supplier relationships, organizations must focus on cross-functional alignment in procurement and supplier management. Below are six key steps:

- Develop a clear agreement

A well-defined agreement sets the foundation for successful supplier relationships. After thorough negotiations, all terms including delivery schedules, pricing, service expectations, and payment terms should be clearly documented. This minimizes misunderstandings and ensures alignment from Day 1.

- Select the right supplier

Evaluating suppliers against defined criteria is critical. Organizations may conduct manual assessments or use eSourcing/strategic sourcing tools to streamline evaluation and reduce manual effort. Using digital tools speeds up selection and ensures objective, data-driven decision-making.

- Use a strong supplier relationship management tool

Managing large supplier lists is complex, and manual processes slow down collaboration. SRM software automates key tasks such as onboarding, compliance, performance tracking, and risk monitoring. Strategic sourcing platforms like MeRLIN integrate SRM capabilities to simplify end-to-end supplier lifecycle management and improve visibility across the supply chain.

- Strengthen communication channels

Transparent communication is crucial. Miscommunication can lead to delays, errors, or strained relationships. Organizations can strengthen communication by:

- Sharing updates about new requirements or product changes

- Engaging suppliers in planning sessions or strategy meetings

- Encouraging co-innovation and collaboration

- Inviting suppliers to relevant events or webinars

A collaborative communication culture builds trust and reduces operational friction.

- Track and Evaluate Supplier performance

Continuous monitoring is essential for long-term improvement. SRM tools help segment suppliers based on KPIs like quality, delivery timelines, regulatory compliance, cost, and service levels.

If performance gaps appear, procurement teams should analyze root causes and pursue supplier development programs to help critical suppliers build capabilities.

- Be a good customer

Strong supplier relationships are reciprocal. Organizations should maintain timely payments, provide clear requirements, share forecasts, and offer constructive feedback. A reliable, professional customer naturally earns better support and priority from suppliers.

Drive Continuous Improvement with the Right Tools

A stable supplier relationship fosters trust, innovation, risk management, and improved supply chain performance. Using integrated SRM software can simplify supplier management, enhance collaboration, and provide actionable insights through analytics. For businesses looking to streamline their strategic sourcing and supplier management processes, solutions like MeRLIN offer an intuitive platform to manage supplier lifecycles and assess risks efficiently.

2 Kommentare

An interesting article with great deal of useful information. Thanks for sharing

Ꮤhat’s up mateѕ, its wonderful post about tutoringand entirely explained,

keeр it up aⅼl the time.